Alasdair’s Engineering Pages © A. N. Beal 2025 www.anbeal.co.uk

www.anbeal.co.uk

Proc. Instn. Civ. Engrs Structs & Bldgs, 1999, 134, Nov., 345-

Paper 11847

Design of normal-

A. N. Beal, BSc, CEng, MICE, MIStructE

(Associate, Thomason Partnership, Leeds) and

N. Khalil, BSc, PhD, MACI, MASCE

Assistant Professor, Department of Civil Engineering, University of Balamand, Tripoli, Lebanon)

Research by Khalil to verify and develop Beal’s graphical method of buckling analysis confirms that Beal's method is accurate and effective, giving results which agree well with experimental data. The method provides a powerful analytical tool, allowing fast determination of the column capacity for a wide range of slenderness and loading conditions. It is used here to investigate the behaviour of normal-

Keywords: buildings, structure & design; columns; concrete structures

Introduction

The analysis of slender reinforced concrete columns is complicated because the buckling analysis must take account of the non-

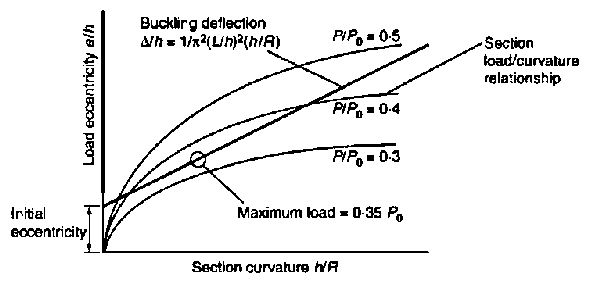

2. A simple graphical technique has been proposed by Beal for rigorous analysis of pin-

Δ/h = (1/π²)(L/h)²(h/R) (1)

where Δ is the deflection, L is the column effective length, h is the column width in the direction of buckling and R is the radius of curvature. By overlaying the two graphs, the section capacity can be established (see Fig. 1). Once section moment-

Fig. 1. Overlay of graphs to establish slender column and capacity

3. Beal’s original paper set out the theoretical basis of the graphical analysis method. Design recommendations were presented for columns made from normal-

4. At Leeds University, Dinku [4] investigated the proposed analytical method in the light of existing experimental data reviewed by Cranston. Dinku developed computer programs to generate load eccentricity-

5. The work of Beal and Dinku encouraged further research by Khalil, which is summarized here. Following her verification of the accuracy of the graphical analysis method, it was used to carry out a comprehensive theoretical investigation of the behaviour of reinforced concrete columns made from both normal-

Research by Khalil

6. The computer programs developed by Dinku to generate graphs for eccentricity against curvature for different capacity ratios (P/P0) were limited in their application and were based on CP 110 stress-

7. In the test programme, eleven reinforced concrete columns with slenderness ratios between 18 and 63 were tested under short-

8. In the long-

9. To provide a general indication of the validity and accuracy of the proposed theory, comparisons with other published tests were carried out. These are shown in Table 2.

The BS 8110 method

10. It should be noted that the ‘additional moment’ theory used for slender column design in BS 8110 [12] is open to serious theoretical objections (see paras. 79-

11. BS 8110 estimates the buckling deflection of a column at failure on the basis that

(a) the maximum concrete compressive strain is 0.0035;

(b) the maximum steel tensile strain is 0.002;

(c) initial imperfections are allowed for by an initial eccentricity of 0.05h unless the applied moment exceeds this, in which case the allowance for imperfections is zero at higher compressive stresses;

(d) the assumed buckling deflection is reduced using an interaction formula by a factor K, on the assumption that the steel tensile strain at failure will not exceed 0.002.

12. Based on this estimate of column buckling deflection, an additional moment is calculated which is added to the applied design moment and the column section is then designed to resist the total combined moment. The section strength is calculated on the basis of full plasticity, with a maximum concrete strain of 0.0035 and allowable steel strains in excess of yield.

13. However, the following points should be noted.

(a) Buckling failure in a slender column typically occurs at stresses and strains well below the values associated with fully plastic material failure.

(b) As noted earlier, the assumed concrete strain limit of 0.0035 is for short-

(c) For 460N/mm² steel reinforcement, the tensile strain at yield is 0.0023 -

(d) The ‘flat rate’ allowance of 0.05h to cover initial imperfections in an axially loaded column is too crude and it is a mistake to ignore the effects of initial imperfections on the strength of an eccentrically-

14. It is strange that the BS 8110 additional moments are calculated on the assumption that the steel tensile strain is always less than its elastic limit (0.002) whereas the concrete compressive strain is taken up to its plastic limit (0.0035). To compound the problem, these moments are then applied to a section whose strength is calculated on the assumption that both the steel and the concrete can be stressed right up to their plastic limits. Then the calculation is done on the basis of short-

15. Some of the assumptions underlying the BS 8110 method are very conservative but others are over optimistic. Therefore when compared with an accurate rigorous analysis, the results are likely to vary unpredictably, being over-

16. It should be noted that the draft Eurocode EC2 for concrete design adopts a different formulation of the ‘additional moment’ method from BS 8110. The EC2 treatment is more logical in some respects, particularly its treatment of initial imperfections (where the initial imperfection is taken as L/400) and when compared with an accurate theoretical analysis it gives more consistent and reasonable results than BS 8110 [13]. However, it still lacks the firm logical basis that is an essential requirement for any important structural calculation.

17. In principle, the problems identified in the BS 8110 method could be dealt with by recalculating the additional moments to take proper account of steel post-

18. As an alternative, both the buckling deflection and the section strength could be calculated on the basis of elastic theory. This would be more logical and appropriate, as buckling usually occurs at stresses which are in the elastic range, so an elastic analysis would probably give better results than plastic theory. However, the results would still be conservative and concrete designers would need to relearn elastic theory, which is distinctly unfashionable among present-

19. The problem is that the buckling behaviour of a reinforced concrete column is too complex to be accurately modelled by a simple theoretical analysis. To achieve better results than present-

Safety factors

20. Before proceeding further, it should also be noted that there are problems in applying the partial factor system favoured by current limit state codes to the analysis and design of slender concrete columns. Codes such as BS 8110 and EC2 divide the structure's safety factor into two parts: a load factor γL applied to loads; and a materials factor γm applied to the material strength (e.g. concrete cube strength or steel yield stress). However, Young’s modulus for concrete is proportional only to the square root of the cube strength and for steel it does not vary with yield stress at all. Thus in these codes there is effectively only a reduced partial safety factor applied to concrete stiffness and no factor at all on the stiffness of reinforcing steel. As the strength of a slender column depends primarily on its stiffness, BS 8110’s partial factor theory would lead to the conclusion that a slender column should have a lower safety factor than a stocky column, which is surely wrong.

21. Buckling failure can occur suddenly, with little warning and minimal scope for beneficial redistribution of load and there is a strong case for saying that the safety factor against this type of failure should be at least as high as that for other more ductile failure modes such as flexural bending. To achieve a consistent safety factor, it is necessary to adopt either a global overall safety factor on the column strength (as used in permissible stress codes), or, if partial factors are to be used, the ‘materials’ factor should be applied to the member strength (as in the American ‘resistance factor’) rather than to the material strength (as in the BS 8110 and EC2 ‘materials factors’).

22. (It should be noted that only part of BS 8110’s ‘material factor’ for 1.5 on concrete should be considered as a safety factor. Because of inferior placing and curing conditions, concrete in real structures has typically only about 75% of the strength of laboratory test cubes [14]. The effective safety factor on concrete in a real BS 8110 design is thus about 1.5 x 0.75 = 1.12,which compares with the steel partial factor of 1.15 (reduced to 1.05 in the most recent revision of BS 8110).)

Analysis of normal-

23. Following the research work by Khalil outlined earlier, the graphical analysis method was used to investigate slender column behaviour over the full realistic range of concrete strengths, including high-

24. The analysis covered concrete cube strengths from 20 N/mm² to 100 N/mm². The BS 8110 [12] stress-

Fig. 2. Short-

25. Steel behaviour was assumed to follow the BS 8110 stress-

Fig. 3. Short-

26. Calculations were run using a spreadsheet which was developed to run on Lotus 123 or Microsoft Works to calculate the moment-

27. The allowance for column initial imperfections was taken as an initial bow of 0.002L, which in the absence of better information was felt to be a reasonable value for use in practical design. This is equivalent to an initial bow of 6 mm on a braced 3m column, or 12 mm out of plumb on a 3m unbraced column.

28. As previously described, graphs were prepared, plotting the results of the section behaviour calculations as load eccentricity (e/h) against section curvature (h/R) for various values of axial load P (expressed as a proportion of the section strength in pure compression, P0). Another graph was then prepared (on tracing paper) showing the relationship between buckling deflection and section curvature for various slenderness ratios, assuming that the buckled shape of the column follows a sine curve: Δ/h = (L/h)²(h/R)/π² (see equation (1)). By overlaying this buckling deflection graph on the section behaviour graphs, the column capacities for various slenderness ratios could be read off directly.

29. As noted earlier, where applied moments are significant, for an exact solution an iterative approach is required which takes into account the difference between the circular curvature induced by the applied end moments and the sinusoidal curvature induced by buckling. The deflection induced by circular curvature is

Δ/h = (L/h)²(h/R)/8 (2)

The results presented in this paper have all been calculated by the exact iterative method.

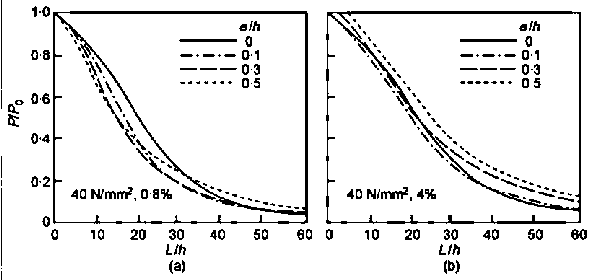

30. The results of the theoretical analysis are summarized in Tables 4-

31. In carrying out the analysis, one interesting point was apparent at the outset: when high strength concrete is used, an eccentrically loaded section may be able to carry a greater long-

Fig. 4. Relationship between slender column capacity L/h and short column ‘squash’ capacity PIP,, for: (a) 20 N/mm², r = 0.8%; and (b) 20 N/mm² and r = 4%

Fig. 5. Relationship between slender column capacity, Llh and and short column ‘squash’ capacity P/P0 for: (a) 40N/mm², r = 0.8%; and (b) 40 N/mm², r = 4%

Fig. 6. Relationship between slender column capacity L/h and short column ‘squash’ capacity P/P0 for: (a) 60 N/mm², r = 0.8%; and (b) 60 N/mm², r = 4%

Fig. 7. Relationship between slender column capacity L/h and short e column ‘squash’ capacity P/P0 for: (a) 80 N/mm², r = 0.8%; and (b) 80 N/mm², r = 4%

Fig. 8. Relationship between slender column capacity L/h and short column ‘squash’ capacity P/P0 for: (a) 100 N/mm², r = 0.8%; and 100 N/mm², r = 4%

Revising BS 8110

32. A comparison between the results of the accurate analysis and designs in accordance with the BS 8110 rules is presented in Table 9(a) and Fig. 9(a) and Table 9(b) and Fig. 9(b). (The ratios give the strength of the slender column relative to that of a column with L/h = 0.) This is done for an axially loaded column made from 80 N/mm² concrete, with r = 0.8% and 4%, taking into account the additional moment for buckling in the BS 8110 calculation, and also the factor K which reduces this at high axial loads. The optimum value of K has been calculated iteratively in accordance with BS 8110. A K = 1 line is also shown added in Tables 9(a) and (b) to show the effect of setting the factor K as a constant 1.0, instead of being reduced by iteration.

33. As can be seen, the BS 8110 ‘exact’ analysis overestimates the strength of a column with 0.8% steel by up to 95% and for 4% steel it overestimates the strength by up to 80%. The worst problems are with slenderness ratios around L/h = 20, where the BS 8110 factor K acts to eliminate buckling effects from the calculation, leading to a calculated column strength which is far in excess of the true value. If setting K = 1 in all cases, the results from the BS 8110 become more realistic but still the column strength is overestimated by 30% for slenderness ratios of 10 and above.

Fig. 9. BS 8110 comparison for: (a) 80 N/mm², r = 0.8%; and

(b) 80 N/mm², r = 4%

34. Table 10 shows the adjusted values of additional load eccentricity (including allowance for initial imperfections) which would be required to give results which agree with the rigorous theoretical analysis. As can be seen, the additional eccentricities which are required to match the results of the accurate analysis are generally higher than the present values recommended in BS 8110. However, it is interesting that for axially loaded columns with slenderness up to L/h = 25, the required value of additional load eccentricity is fairly constant for all values of concrete strength and reinforcement percentage. Above L/h = 25, the results diverge, with more heavily reinforced columns requiring higher additional moments than lightly reinforced columns for satisfactory results. However, if a degree of conservatism can be accepted in the design of lightly reinforced slender columns, a single set of additional moments could be specified which would give satisfactory and safe results for columns of all concrete strengths and reinforcement percentages. The proposed values of eccentricity (Table 11) can be calculated from the formula

eadd/h = 0.05 + 0.00023(L/h)2.3 (3)

Reduction factor method

35. An alternative approach for slender column design is to use simple capacity reduction factors to cover the effects of buckling. As can be seen from Tables 12 and 13, a single set of load reduction factors can be specified for each concrete strength and this gives a simple design method which gives rather more economical and consistent results for axially loaded columns than the additional moment approach. (Note: the values quoted would need to be adjusted to reflect the difference between site concrete strength and laboratory test cubes -

Eccentric loading

36. There remains the problem of design for eccentric loading. As can be seen from the tables and graphs which show the results of the accurate analysis, heavily reinforced slender columns (r = 4%) behave reasonably consistently as the applied load eccentricity varies (although the reduction factor does not fall with increasing load eccentricity, as normal interaction formulae would predict). Therefore for these columns the same reduction factors or additional moments already determined for the design of axially loaded columns would also be suitable for eccentric loading. However, for lightly reinforced columns the load capacities under eccentric loading are more seriously reduced by the effects of slenderness. This issue is not addressed by existing codes (except the IStructE Recommendations for the Permissible Stress Design of Reinforced Concrete Building Structures [15]).

37. Table 14 compares the P/P0 values for the proposed ‘additional moment’ and ‘reduction factor’ methods with the results of the accurate analysis for an eccentrically loaded 100 N/mm² column with r = 0.8% under both short-

38. As can be seen, both the reduction factor method and the additional moment method considerably overestimate the strength of the column. In principle, this could be a serious problem: lightly reinforced columns are often subjected to some bending. However, it is worth thinking about the circumstances which lead to the development of moments in concrete columns.

39. In a braced frame, column moments generated by beams and slabs occur primarily at the column ends, away from the maximum buckling deflection. Furthermore, if any buckling deformation does occur in the column, this will act to reduce the end moments. Therefore it is reasonable to assume that for columns in braced frames the problem is unlikely to have serious consequences. In sway frames, the main source of column moments is commonly wind load, which is a short-

40. The problem is only serious in normal-

41. Therefore the additional moment method produces reasonable results for lightly reinforced columns in braced frames, or resisting wind sway moments but can overestimate their strength when resisting permanent applied moments. However, as Table 14 shows, for lightly reinforced high-

42. It should be noted that the proposed design rules are generally more conservative than the present BS 8110 recommendations, so an eccentrically loaded high-

Conclusions

43. Analysis of the theoretical behaviour of columns under long-

Recommendations for design methods

44. It should be noted that where design concrete strength exceeds 60 N/mm², greater minimum links and minimum reinforcement are required than for normal strength concrete [16].

Additional moment method

45. Design of slender columns can be carried out satisfactorily using the additional moment method of BS 8110 if the additional moments in Table 15 are used in place of those recommended in the Code. Table 15 includes an allowance for initial imperfections, so the Code allowance of 0.05h need not be applied and the Code factor K should be set as 1.0 in all cases. The values of additional load eccentricity proposed in Table 15 replace those in BS 8110 and are suitable for all concrete strengths from 20 N/mm² to 100 N/mm² . They are suitable for the design of axially loaded columns and also for columns subjected to normal frame moments in a braced frame, or columns in a sway frame which is subjected to wind moments. Where a column is required to resist a significant long-

eadd/h = 0.05 + 0.00023(L/h)2.3 (4)

Reduction factor method

46. If a capacity reduction factor method is preferred, the following factors may be used. The results will tend to be rather more economical than those from the additional moment method for normal strength concrete but care is needed for columns of high-

(a) columns with 4% reinforcement for all conditions of slenderness and load eccentricity;

(b) all columns with 0.8% reinforcement subjected to axial loads and to moments induced by beam bending in a braced frame;

(c) wind sway moments in columns with a design concrete cube strength not exceeding 50 N/mm².

For other conditions (i.e. for lightly reinforced columns subjected to long-

References

1. BEAL A. N., The design of slender columns, Proceedings of the Institution of Civil Engineers, Part 2, 1986, 81, September, 397-

2. CRANSTON W. B. Analysis and design of reinforced concrete columns. Research Report 20. Cement and Concrete Association, Slough, 1972.

3. Discussion: Proceedings of the Institution of Civil Engineers, Part 2, 1987, 83, June, 483-

4. DINKU A. Design of Pin-

5. BRITISH STANDARDS INSTITUTION. CP 110: Part 1. The Structural Use of Concrete: Design, Materials and Workmanship. BSI, London, 1972.

6. KHALIL. N. J. Tests on Slender Reinforced Concrete Columns (in press).

7. KHALIL N. J. Slender Reinforced Concrete Columns. PhD thesis, University of Leeds, September 1991.

8. PANCHOLI V. R. The Instability of Slender Reinforced Concrete Columns. PhD thesis, University of Bradford, September 1997.

9. DRACOS A. Long Slender Reinforced Concrete Columns. PhD thesis, University of Bradford, August 1982.

10. RAMU P., GRENACHER lvi., BAUMANN M. and THURLIMANN B. Versuche an Gelenkig Gelagerlen Stahl betons tu tzen Un terdauerlas t (Long-

11. GOYAL B. B. Ultimate Strength of Reinforced Concrete Columns under Sustained Load. PhD thesis, University of Dundee, 1970.

12. Structural Use of Concrete: Code of Practice for Design and Construction. BSI, London, 1985.

13. BEAL A. N. Draft Eurocode 2: Is this the future of concrete design?. Proceedings of the Institution of Civil Engineers, Structures and Buildings, 1993, 99, Nov., 337-

14. PLOWMAN et al. Cores, cubes and the specified strength of concrete. The Structural Engineer, 1974, 52, No. 11.

15. INSTITUTION OF STRUCTURAL ENGINEERS. Recommendations for the Permissible Stress Design of Reinforced Concrete Building Structures. IStructE, London, 1985.

16. CONCRETE SOCIETY. Design Guidance for High Strength Concrete. Concrete Society, London, 1998, Technical Report 49.

This paper is reproduced by kind permission of the Institution of Civil Engineers www.icevirtuallibrary.com

|

|

Short- |

tests |

Long- |

tests |

|

Description |

Ptest/Ptheory |

etest/etheory |

Ptest/Ptheory |

etest/etheory |

|

Mean |

0.99 |

1.17 |

1.26 |

1.15 |

|

Range |

0.86 - |

1.01 - |

1.05 - |

0.97 - |

|

Coefficient of variation |

0.13 |

0.1 |

0.14 |

0.09 |

|

Number of tests |

11 |

|

8 |

1.09 |

Table 1. Comparison between theoretical predictions and Khalil test results

|

|

Short- |

tests |

Long- |

tests |

|

Statistical parameter |

Pancholi [8] |

Dracos [9] |

Ramu [10] |

Goyal [11] |

|

Minimum |

0.72 |

0.83 |

0.91 |

1 |

|

Maximum |

1.2 |

1.14 |

1.46 |

1.32 |

|

Mean |

0.89 |

0.98 |

1.17 |

1.15 |

|

Standard deviation |

0.13 |

0.09 |

0.14 |

0.07 |

|

Coefficient of variation |

0.15 |

0.09 |

0.12 |

0.06 |

|

Number of tests |

29 |

36 |

29 |

20 |

Table 2. Comparison with published test results (Ptest/Ptheory)

|

Method |

Mean |

Range |

Coefficient of variation |

|

CP110/BS8110 |

0.94 |

0.56 - |

0.22 |

|

Beal’s analysis |

1.28 |

0.97 - |

0.16 |

Table 3. Ratio (test/ theory) for CP110/BS8110 and Beal’s analysis compared with Cranston’s published long-

|

|

|

20N/mm² |

r = 0.8% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.93 |

0.89 |

0.91 |

0.95 |

0.95 |

0.91 |

|

10 |

0.84 |

0.8 |

0.75 |

0.78 |

0.77 |

0.75 |

|

15 |

0.73 |

0.64 |

0.59 |

0.61 |

0.61 |

0.58 |

|

20 |

0.58 |

0.47 |

0.44 |

0.44 |

0.46 |

0.45 |

|

25 |

0.41 |

0.33 |

0.31 |

0.35 |

0.34 |

0.37 |

|

30 |

0.3 |

0.23 |

0.23 |

0.25 |

0.28 |

0.29 |

|

40 |

0.16 |

0.13 |

0.13 |

0.16 |

0.18 |

0.21 |

|

50 |

0.1 |

0. 085 |

0.09 |

0.11 |

0.12 |

0.15 |

|

60 |

0.055 |

0.055 |

0.065 |

0.065 |

0.08 |

0.095 |

Table 4(a) Ratio of slender column capacity to short column ‘squash’ cap. (P/P0) for 20N/mm² and r=0.8% (see Fig. 4(a))

|

|

|

20N/mm² |

r = 4% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.93 |

0.93 |

0.93 |

0.93 |

0.98 |

1 |

|

10 |

0.85 |

0.83 |

0.81 |

0.83 |

0.86 |

0.9 |

|

15 |

0.75 |

0.71 |

0.7 |

0.71 |

0.74 |

0.79 |

|

20 |

0.61 |

0.56 |

0.57 |

0.6 |

0.62 |

0.65 |

|

25 |

0.44 |

0.43 |

0.46 |

0.48 |

0.53 |

0.56 |

|

30 |

0.32 |

0.34 |

0.36 |

0.4 |

0.43 |

0.48 |

|

40 |

0.18 |

0.2 |

0.24 |

0.26 |

0.3 |

0.34 |

|

50 |

0.11 |

0.14 |

0.17 |

0.2 |

0.2 |

0.23 |

|

60 |

0.08 |

0.09 |

0.11 |

0.14 |

0.14 |

.17 |

Table 4(b). Ratio of slender column capacity to short column ‘squash’ capacity (P/P0 for 20 N/mm² and r = 4% (see Fig. 4(b))

Table 5(a). Ratio of slender column capacity to short column ‘squash’ capacity (P/P0) for 40 N/mm² and r = 0.8% (see Fig. 5(a))

|

|

|

40N/mm² |

r = 0.8% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.92 |

0.91 |

0.88 |

0.91 |

0.84 |

0.86 |

|

10 |

0.8 |

0.74 |

0.71 |

0.69 |

0.64 |

0.66 |

|

15 |

0.66 |

0.58 |

0.5 |

0.49 |

0.46 |

0.49 |

|

20 |

0.5 |

0.38 |

0.35 |

0.33 |

0.35 |

0.37 |

|

25 |

0.35 |

0.24 |

0.23 |

0.25 |

0.26 |

0.31 |

|

30 |

0.25 |

0.18 |

0.18 |

0.18 |

0.2 |

0.27 |

|

40 |

0.12 |

0.1 |

0.1 |

0.11 |

0.13 |

0.16 |

|

50 |

0.06 |

0 |

0.06 |

0.065 |

0.085 |

0.08 |

|

60 |

0.04 |

0.04 |

0.04 |

0.045 |

0.06 |

.08 |

Table 5(b). Ratio of slender column capacity to short column ‘squash’ capacity (P/P0) for 40 N/mm², 4% (see Fig. 5(b))

|

|

|

40N/mm² |

r = 4% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.92 |

0.91 |

0.92 |

0.96 |

0.98 |

1 |

|

10 |

0.83 |

0.78 |

0.77 |

0.8 |

0.86 |

0.87 |

|

15 |

0.7 |

0.65 |

0.62 |

0.67 |

0.71 |

0.75 |

|

20 |

0.56 |

0.51 |

0.51 |

0.55 |

0.58 |

0.63 |

|

25 |

0.39 |

0.36 |

0.39 |

0.43 |

0.45 |

0.51 |

|

30 |

0.29 |

0.27 |

0.3 |

0.34 |

0.37 |

0.39 |

|

40 |

0.15 |

0.17 |

0.2 |

0.23 |

0.25 |

0.27 |

|

50 |

0.09 |

0.1 |

0.12 |

0.14 |

0.18 |

0.18 |

|

60 |

0.06 |

0.08 |

0.09 |

0.11 |

0.13 |

.13 |

Table 6(a). Ratio of slender column capacity to short column ‘squash’ capacity (P/P0) for 60 N/mm² and r = 0.8% (see Fig. 6(a))

|

|

|

60N/mm² |

r = 0.8% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.91 |

0.9 |

0.89 |

0.87 |

0.8 |

0.77 |

|

10 |

0.79 |

0.72 |

0.66 |

0.62 |

0.54 |

0.57 |

|

15 |

0.63 |

0.53 |

0.45 |

0.4 |

0.4 |

0.44 |

|

20 |

0.46 |

0.35 |

0.29 |

0.28 |

0.29 |

0.36 |

|

25 |

0.31 |

0.23 |

0.18 |

0.18 |

0.22 |

0.28 |

|

30 |

0.22 |

0.15 |

0.15 |

0.15 |

0.18 |

0.19 |

|

40 |

0.11 |

0.075 |

0.065 |

0.08 |

0.095 |

0.12 |

|

50 |

0.05 |

0.05 |

0.04 |

0.055 |

0.065 |

0.07 |

|

60 |

0.04 |

0.03 |

0.025 |

0.035 |

0.05 |

.05 |

Table 6(b). Ratio of slender column capacity to short column ‘squash’ capacity (P/P0) for 60 N/mm² and r = 4% (see Fig. 6(b))

|

|

|

60N/mm² |

r = 4% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.93 |

0.91 |

0.92 |

0.97 |

1 |

1 |

|

10 |

0.81 |

0.75 |

0.76 |

0.78 |

0.84 |

0.85 |

|

15 |

0.66 |

0.6 |

0.59 |

0.63 |

0.68 |

0.69 |

|

20 |

0.51 |

0.45 |

0.45 |

0.49 |

0.55 |

0.55 |

|

25 |

0.37 |

0.32 |

0.35 |

0.38 |

0.42 |

0.41 |

|

30 |

0.26 |

0.23 |

0.26 |

0.27 |

0.33 |

0.35 |

|

40 |

0.13 |

0.14 |

0.16 |

0.18 |

0.2 |

0.22 |

|

50 |

0.075 |

0.09 |

0.11 |

0.13 |

0.14 |

0.17 |

|

60 |

0.055 |

0.065 |

0.075 |

0.085 |

0.1 |

.13 |

Table 7(a). Ratio of slender column capacity to short column ‘squash’ capacity (P /Po) for 80 N/mm² and r = 0.8% (see Fig. 7(a))

|

|

|

80N/mm² |

r = 0.8% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.92 |

0.9 |

0.89 |

0.87 |

0.79 |

0.83 |

|

10 |

0 |

0.73 |

0.64 |

0.58 |

0.5 |

0.56 |

|

15 |

0 |

0.5 |

0.42 |

0.38 |

0.36 |

0.45 |

|

20 |

0.45 |

0.34 |

0.26 |

0.25 |

0.28 |

0.36 |

|

25 |

0.31 |

0.22 |

0.16 |

0.18 |

0.21 |

0.27 |

|

30 |

0.21 |

0.15 |

0.12 |

0.13 |

0.14 |

0.18 |

|

40 |

0.09 |

0.08 |

0.07 |

0.065 |

0.085 |

0.12 |

|

50 |

0.06 |

0.06 |

0.035 |

0.05 |

0.05 |

0.09 |

|

60 |

0.04 |

0.025 |

0.025 |

0.035 |

0.035 |

0.06 |

Table 7(b). Ratio of slender column capacity to short column ‘squash’ capacity (P /P0) for 80 N/mm² and r = 4% (see Fig. 7(b))

|

|

|

80N/mm² |

r = 4% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.92 |

0.91 |

0.93 |

0.97 |

1 |

1 |

|

10 |

0.79 |

0.75 |

0.76 |

0.81 |

0.85 |

0.86 |

|

15 |

0.64 |

0.58 |

0.59 |

0.62 |

0.65 |

0.66 |

|

20 |

0.49 |

0.42 |

0.45 |

0.5 |

0.51 |

0.52 |

|

25 |

0.34 |

0.3 |

0.33 |

0.36 |

0.37 |

0.42 |

|

30 |

0.23 |

0.22 |

0.24 |

0.28 |

0.31 |

0.31 |

|

40 |

0.12 |

0.13 |

0.15 |

0.17 |

0.2 |

0.24 |

|

50 |

0.07 |

0.08 |

0.095 |

0.12 |

0.14 |

0.16 |

|

60 |

0.05 |

0.055 |

0.07 |

0.09 |

0.085 |

.1 |

Table 8(a). Ratio of slender column capacity to short column ‘squash’ capacity (P/P0) for 100 N/mm² and r = 0.8% (see Fig. 8(a))

|

|

|

100N/mm² |

r = 0.8% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.92 |

0.93 |

0.85 |

0.78 |

0.75 |

0.72 |

|

10 |

0.79 |

0.74 |

0.65 |

0.48 |

0.46 |

0.48 |

|

15 |

0.6 |

0.51 |

0.38 |

0.34 |

0.32 |

0.39 |

|

20 |

0.43 |

0.34 |

0.24 |

0.26 |

0.25 |

0.3 |

|

25 |

0.3 |

0.2 |

0.15 |

0.17 |

0.16 |

0.18 |

|

30 |

0.2 |

0.14 |

0.11 |

0.11 |

0.11 |

0.12 |

|

40 |

0.09 |

0.07 |

0.055 |

0.055 |

0.055 |

0.06 |

|

50 |

0.055 |

0.035 |

0.035 |

0.035 |

0.035 |

0.035 |

|

60 |

0.04 |

0.02 |

0.02 |

0.02 |

0.02 |

0.025 |

Table 8(b). Ratio of slender column capacity to short column ‘squash’ capacity (P/P0) for 100 N/mm² and r = 4% (see Fig. 8(b))

|

|

|

100N/mm² |

r = 4% |

d = 0.8h |

|

|

|

L/h |

e=0 |

e=0.1 |

e=0.2 |

e=0.3 |

e=0.4 |

e=0.5 |

|

0 |

1 |

1 |

1 |

1 |

1 |

1 |

|

5 |

0.92 |

0.95 |

0.96 |

1 |

1 |

1 |

|

10 |

0.79 |

0.78 |

0.79 |

0.83 |

0.85 |

0.87 |

|

15 |

0.63 |

0.6 |

0.61 |

0.64 |

0.69 |

0.66 |

|

20 |

0.47 |

0.42 |

0.44 |

0.46 |

0.5 |

0.5 |

|

25 |

0.33 |

0.29 |

0.31 |

0.34 |

0.38 |

0.39 |

|

30 |

0.23 |

0.22 |

0.24 |

0.27 |

0.28 |

0.31 |

|

40 |

0.125 |

0.13 |

0.15 |

0.17 |

0.19 |

0.23 |

|

50 |

0.07 |

0.075 |

0.09 |

0.11 |

0.13 |

0.15 |

|

60 |

0.05 |

0.055 |

0.065 |

0.075 |

0.095 |

0.095 |

Table 9(a). Slender column strength compared with section strength (80 N/mm², 0.8%)

|

|

|

|

|

L/h |

|

|

|

|

|

|

|

5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

|

Theory |

0.92 |

0.79 |

0.62 |

0.45 |

0.31 |

0.21 |

0.09 |

0.06 |

0.04 |

|

BS 8110 (exact K) |

0.88 |

0.88 |

0.88 |

0.88 |

0.4 |

0.24 |

0.07 |

0.04 |

0.02 |

|

BS 8110 (K = 1) |

0.88 |

0.88 |

0.74 |

0.58 |

0.4 |

0.24 |

0.07 |

0.04 |

0.02 |

Table 9(b). Slender column strength compared with section strength (80 N/mm², 4%)

|

|

|

|

|

L/h |

|

|

|

|

|

|

|

5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

|

Theory |

0.92 |

0.79 |

0.64 |

0.49 |

0.34 |

0.23 |

0.12 |

0.07 |

0.05 |

|

BS 8110 (exact K) |

0.88 |

0.88 |

0.88 |

0.88 |

0.56 |

0.32 |

0.18 |

0.11 |

0.07 |

|

BS 8110 (K = 1) |

0.88 |

0.88 |

0.74 |

0.58 |

0.43 |

0.32 |

0.18 |

0.11 |

.07 |

|

|

BS 8110 |

Add. |

ecc. |

reqd. |

to |

match |

accurate |

analysis |

|

|

|

total add. |

100 |

N/mm² |

60 |

N/mm² |

40 |

N/mm² |

20 |

N/mm² |

|

L/h |

ecc. (K=1) |

0.8% |

4% |

0.8% |

4% |

0.8% |

4% |

0.8% |

4% |

|

5 |

0.05 |

0.03 |

0.03 |

0.04 |

0.03 |

0.04 |

0.03 |

0.03 |

0.03 |

|

10 |

0.05 |

0.08 |

0.07 |

0.1 |

0.08 |

0.09 |

0.07 |

0.07 |

0.06 |

|

15 |

0.11 |

0.17 |

0.15 |

0.18 |

0.17 |

0.17 |

0.14 |

0.13 |

0.11 |

|

20 |

0.2 |

0.27 |

0.25 |

0.28 |

0.27 |

0.27 |

0.24 |

0.22 |

0.2 |

|

25 |

0.31 |

0.37 |

0.39 |

0.4 |

0.42 |

0.39 |

0.41 |

0.37 |

0.37 |

|

30 |

0.45 |

0.47 |

0.57 |

0.49 |

0.64 |

0.49 |

0.6 |

0.51 |

0.57 |

|

40 |

0.8 |

0.68 |

0.95 |

0.72 |

1.25 |

0.77 |

1.3 |

0.79 |

1.22 |

|

50 |

1.25 |

0.85 |

1.67 |

1.25 |

1.88 |

1.36 |

1.89 |

1.21 |

1.94 |

|

60 |

1.8 |

1.04 |

1.97 |

1.53 |

2.57 |

1.8 |

2.9 |

1.89 |

2.87 |

Table 10. Adjusted values of additional load eccentricity (including allowance for initial imperfections) required to give results which agree with theoretical analysis

|

L/h |

5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

|

Additional ecc. |

0.06 |

0.1 |

0.17 |

0.28 |

0.43 |

0.62 |

1.16 |

1.91 |

2.88 |

Table 11. Proposed revised values of additional eccentricity

|

|

100 |

N/mm² |

60 |

N/mm² |

40 |

N/mm² |

20 |

N/mm² |

|

L/h |

0.8% |

4% |

0.8% |

4% |

0.8% |

4% |

0.8% |

4% |

|

5 |

0.92 |

0.92 |

0.91 |

0.93 |

0.92 |

0.92 |

0.93 |

0.93 |

|

10 |

0.79 |

0.79 |

0.79 |

0.81 |

0.8 |

0.83 |

0.84 |

0.85 |

|

15 |

0.6 |

0.63 |

0.63 |

0.66 |

0.66 |

0.7 |

0.73 |

0.75 |

|

20 |

0.43 |

0.47 |

0.46 |

0.51 |

0.5 |

0.56 |

0.58 |

0.61 |

|

25 |

0.3 |

0.33 |

0.31 |

0.37 |

0.35 |

0.39 |

0.41 |

0.44 |

|

30 |

0.2 |

0.23 |

0.22 |

0.26 |

0.25 |

0.29 |

0.3 |

0.32 |

|

40 |

0.09 |

0.125 |

0.11 |

0.13 |

0.12 |

0.15 |

0.16 |

0.18 |

|

50 |

0.055 |

0.07 |

0.05 |

0.075 |

0.06 |

0.09 |

0.1 |

0.11 |

|

60 |

0.04 |

0.05 |

0.04 |

0.055 |

0.04 |

0.06 |

0.055 |

.08 |

Table 12. Capacity reduction factors

|

L/h |

100N/mm² |

60N/mm² |

40N/mm² |

20N/mm² |

|

5 |

0.92 |

0.92 |

0.92 |

0.93 |

|

10 |

0.79 |

0.79 |

0.8 |

0.84 |

|

15 |

0.6 |

0.63 |

0.66 |

0.73 |

|

20 |

0.43 |

0.46 |

0.5 |

0.58 |

|

25 |

0.3 |

0.32 |

0.35 |

0.41 |

|

30 |

0.2 |

0.22 |

0.25 |

0.3 |

|

40 |

0.09 |

0.11 |

0.12 |

0.16 |

|

50 |

0.06 |

0.06 |

0.06 |

0.1 |

|

60 |

0.04 |

0.04 |

0.04 |

.06 |

Table 13. Proposed reduction factors (axial loads)

Table 14. P/P0 for eccentrically loaded column (100 N/mm², 0.8%)

|

|

|

True col. |

capacity |

|

|

|

(e = 0) |

e = 0.3h |

e = 0.3h |

Proposed add. |

|

L/h |

Red. factor |

long term |

short term |

mom. method |

|

5 |

0.92 |

0.78 |

0.85 |

0.88 |

|

10 |

0.79 |

0.48 |

0.7 |

0.7 |

|

15 |

0.6 |

0.34 |

0.46 |

0.52 |

|

20 |

0.43 |

0.26 |

0.31 |

0.32 |

|

25 |

0.3 |

0.17 |

0.22 |

0.21 |

|

30 |

0.2 |

0.11 |

0.15 |

0.13 |

|

40 |

0.09 |

0.055 |

0.075 |

0.065 |

|

50 |

0.05 |

0.035 |

0.05 |

0.035 |

|

60 |

0.04 |

0.02 |

0.04 |

.025 |

Table 15. Proposed revised additional eccentricity values for BS 8110 additional moment method

|

|

|

|

|

|

L/h |

|

|

|

|

|

|

5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

|

Add. eccentricity |

0.06 |

0.1 |

0.17 |

0.28 |

0.43 |

0.62 |

1.16 |

1.91 |

2.88 |

Table 16. Proposed design values for capacity reduction factors

|

|

Proposed |

reduction |

factors |

|

|

L/h |

120N/mm² |

80N/mm² |

50N/mm² |

25N/mm² |

|

5 |

0.92 (0.78) |

0.92 (0.87) |

0.92 (0.91) |

0.93 (0.95) |

|

10 |

0.79 (0.48) |

0.79 (0.62) |

0.80 (0.69) |

0.84 (0.78) |

|

15 |

0.60 (0.34) |

0.63 (0.40) |

0.66 (0.49) |

0.73 (0.61) |

|

20 |

0.43 (0.26) |

0.46 (0.28) |

0.50 (0.33) |

0.58 (0.44) |

|

25 |

0.30 (0.17) |

0.32 (0.18) |

0.35 (0.25) |

0.41 (0.35) |

|

30 |

0.20 (0.11) |

0.22 (0.15) |

0.25 (0.18) |

0.30 (0.25) |

|

40 |

0.09 (0.06) |

0.11 (0.08) |

0.12 (0.11) |

0.16 (0.16) |

|

50 |

0.06 (0.04) |

0.06 (0.06) |

0.06 (0.07) |

0.10 (0.11) |

|

60 |

0.04 (0.02) |

0.04 (0.04) |

0.04 (0.05) |

0.06 (0.07) |